- 4/15, Agilmedu 5th Street, Erode, TN - 01.

- rightwatersolution11@gmail.com

- +91 98430 78767

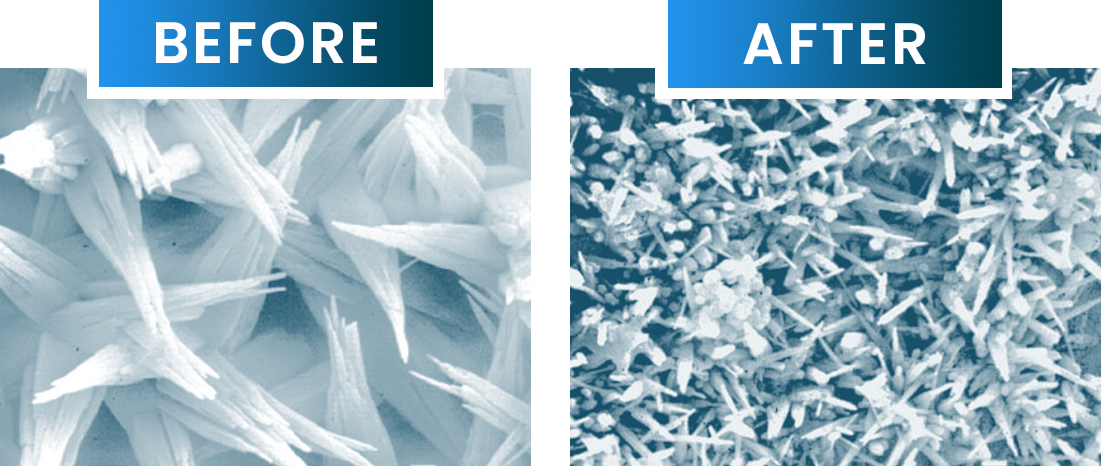

Hard Water consists of heavy molecules of calcium and magnesium, which stick to each other and to the surfaces instead of flowing with the water. These deposits become solid and crystallized when untreated. When you treat hard water with Anti-scaling system, the impulse changes the shape of calcium and magnesium particles.

Kashyap Anti-scale system breaks their adhesive power and prevents their crystallization. As a result, the particles turn into a fine powder and washes away along the water. This is how Kashyap prevents the accumulation of new scales on surfaces as well as inside the pipes.

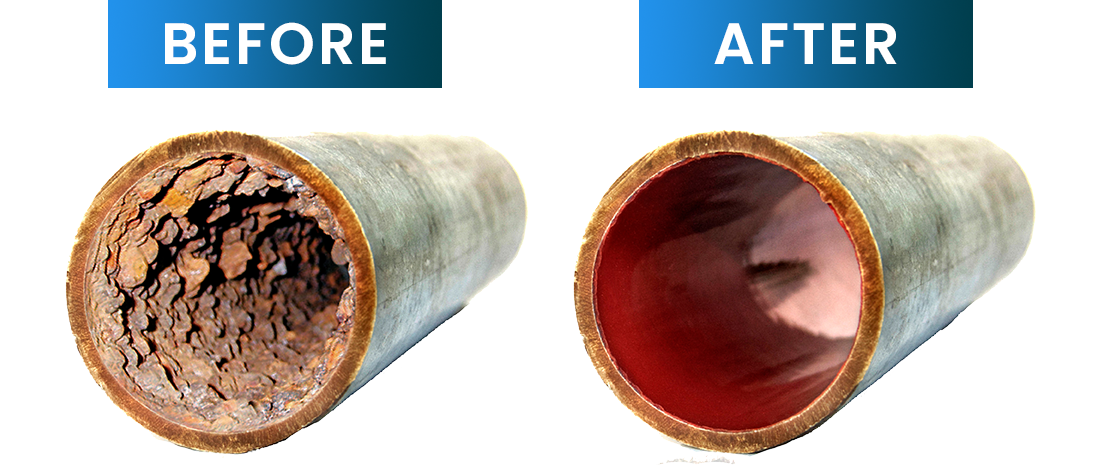

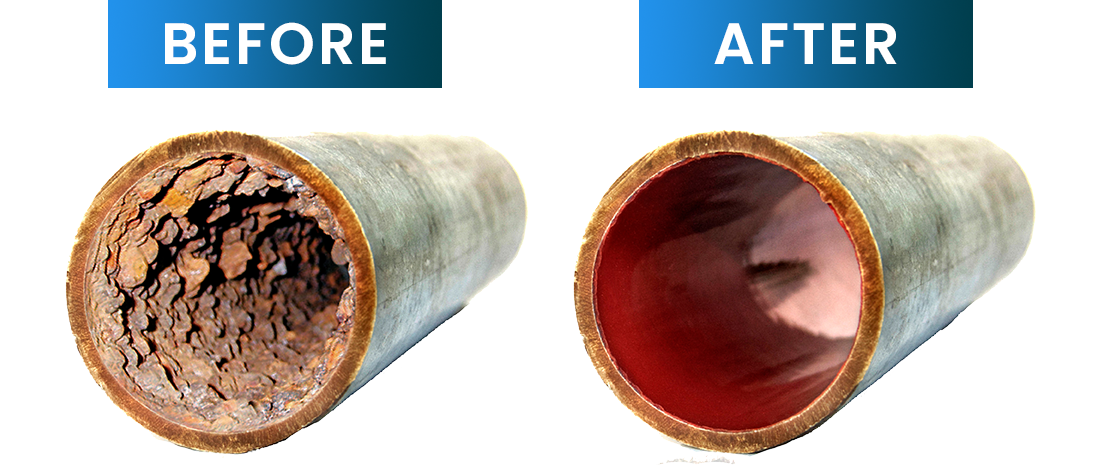

Calcium particles stick to each other and fasten the process of scale deposition inside the pipes. These deposits produce carbonic acid (H2CO3), which breaks down the existing scale deposits naturally. Although this is how the scales are removed naturally, it doesn’t solve the issue as the build-up process is faster than the resolving process. The deposition increases with time, which ultimately reduces the diameter of pipes.

With Kashyap anti-scaling system, this process is reversed as electronic impulse doesn’t allow the deposition of scales. The rate of scale deposits becomes much slower, eliminating the scale-build up entirely. As the scale eradication becomes faster than the build-up process, it also removes the existing deposits more effectively. The carbonic acid generated during the process keeps dissolving the scales sanitizing the piping system.

Iron and copper oxidation occurs in all metal pipes when it comes in contact with hard water. These oxides have an adverse effect on pipe surfaces and can even cause corrosion.

Anti-scaling system with the impulse develops an electrophoresis effect and makes a protected metal-carbonate covering on the pipe. It consists of copper-carbonate, iron-carbonate, or zinc-carbonate depending upon the type of pipe material which stays overall shiny metal surfaces. This layer helps in protecting the pipes against aggressive substances that can cause corrosion

| Model | Capacity | Max. Pipe Diameter | Impulse Cable | Required Space Approx | Voltage | In | Out | |

|---|---|---|---|---|---|---|---|---|

| Residential | K-2 | 2 m3/h | 1" (25 mm) | 1m x 2 | 400 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

| K-10 | 10 m3/h | 2" (50 mm) | 3m X 2 | 800 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

|

| Commercial | K-25 | 25 m3/h | 3" (75 mm) | 3m X 4 | 950 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

| K-50 | 50 m3/h | 4" (100 mm) | 4m X 4 | 1200 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

|

| K-100 | 100 m3/h | 6" (150 mm) | 5m X 6 | 1500 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

|

| Industrial | K-200 | 200 m3/h | 8" (200 mm) | 10m X 8 | 2700 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

| K-350 | 350 m3/h | 14" (350 mm) | 16m X 10 | 3000 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

|

| K-500 | 500 m3/h | 20" (500 mm) | 25m X 12 | 8000 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

|

| K-1000 | 1000 m3/h | 30" (760 mm) | 30m X 16 | 15,000 mm | 24 Volt DC | 87-260 Volt 50-60Hz |

24 Volt 625 mA |

WATCH® SOFT-NO-R uses revolutionary FILTERSORB® SP3 media inside a pressure vessel which is running in a counter current mode. The up flowing water causes the formation of a fluidized bed of the media. The immediate conversion of water hardness (due to Ca2+ and Mg2+) gets converted into sub-micron size harmless crystal when hard water passes through the media. The height of the pressure vessel is chosen depending on the maximum flow rate of the unit, to provide the required space for the expansion of the floating bed. It's recommended to use a pressure vessels whose volume is 6 - 7 times than the volume of the media used.

The FILTERSORB® SP3 media completely takes care of the temporary water hardness, irrespective of the hardness level of the water*. The average life expectancy of the media is around 3 - 5 years, depending on the water condition.

WATCH® SOFT-NO-R media, FILTERSORB® SP3 will be blocked if H2S, oil and grease are present in the water. There must not be any Iron and Manganese in the water (WHO conform). For 24hr per day operation we recommend a dual train unit. The SP3 media is heat resistant up to 120°C.

It's recommended to maintain a chlorine content up to 2ppm maximum.